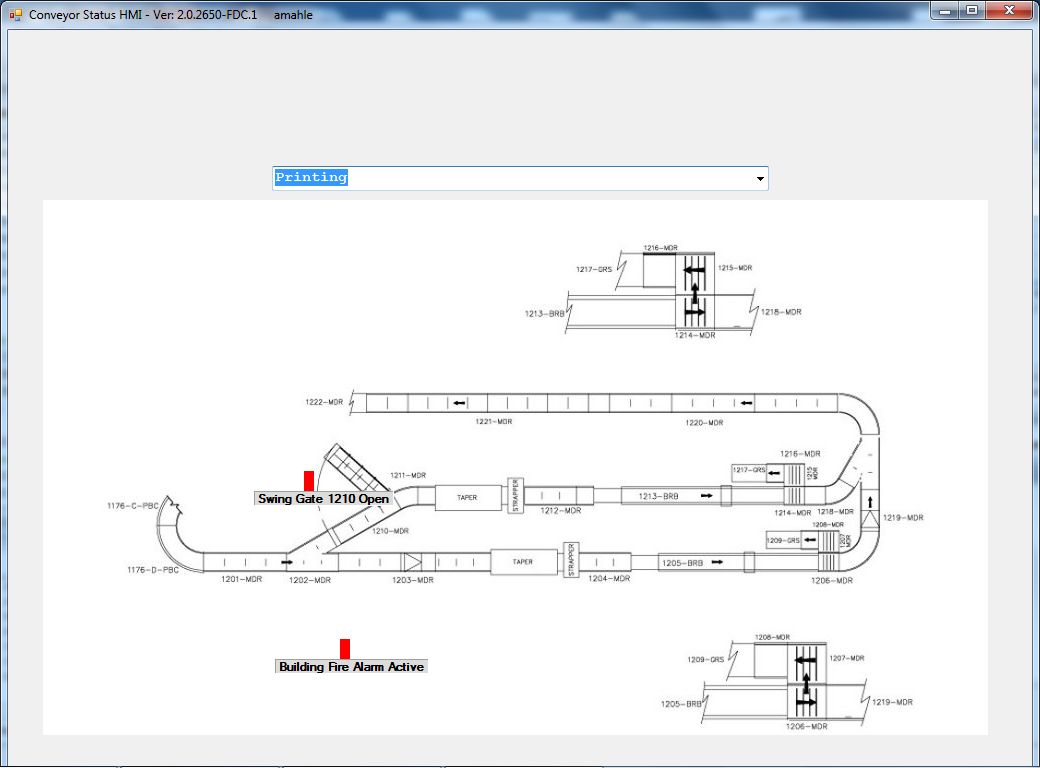

Conveyor Status – Conveyor Status provides information regarding faults throughout the conveyor system. Each device or condition that requires fault detection (motor overloads, E-stop tripped, gate up, slack chain sensor, product jam, etc.) will be monitored. When a fault occurs, a description of the fault will be displayed on a screen that represents the conveyor layout for that area. The time the fault occurred and when it is resolved are recorded.

Other conditions that are not faults but are of operator interest are also displayed. These include accumulation full status where applicable, functional areas running / not running, operational modes, etc.

The operator is provided with a drop down list to select which area should be displayed. A screen will appear depicting the selected area and indicating active fault, alarm or status conditions.

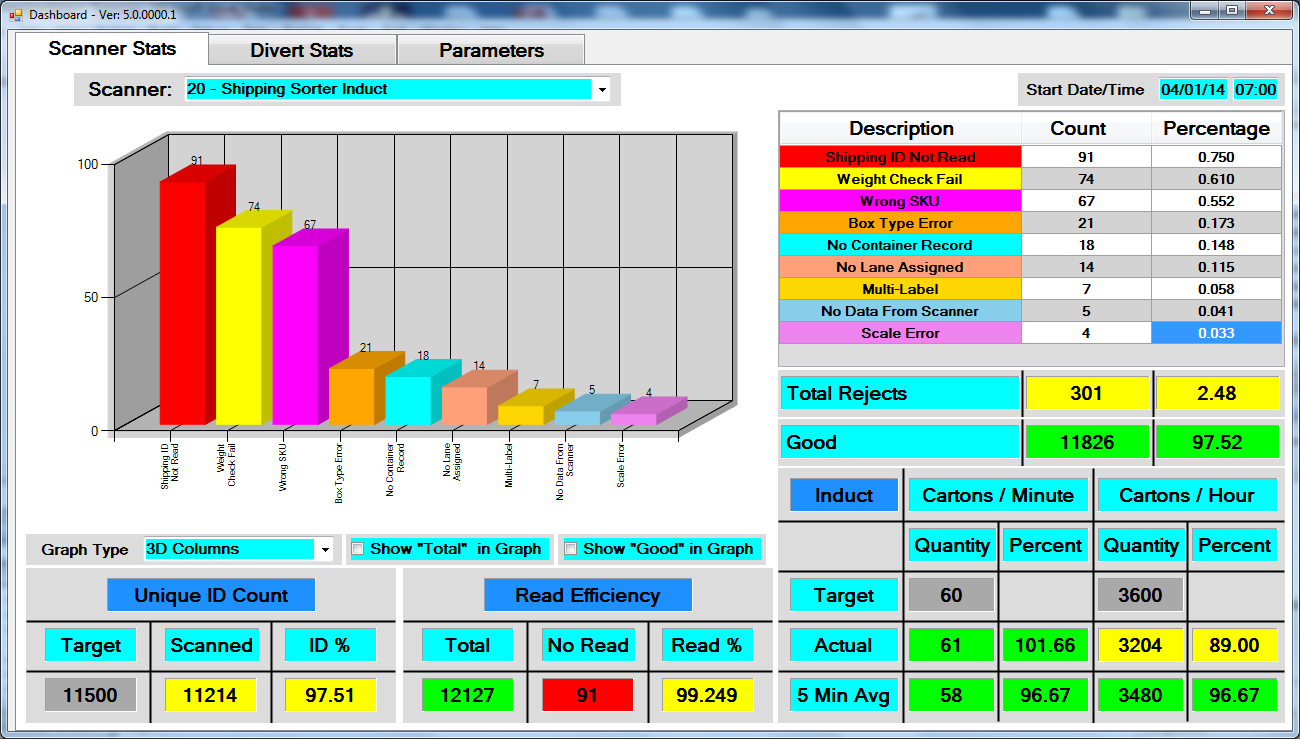

·Dashboard - The Dashboard provides a quick view of how a scanner and the associated area are functioning. Parameters can be set for each scanner to allow for target counts, rates and percentages. The user can select the scanner to view, type of graph to display and whether to include Total cartons and Good cartons as part of the graph. The descriptions for the Reject types are dependent upon the area type and the user requirements.

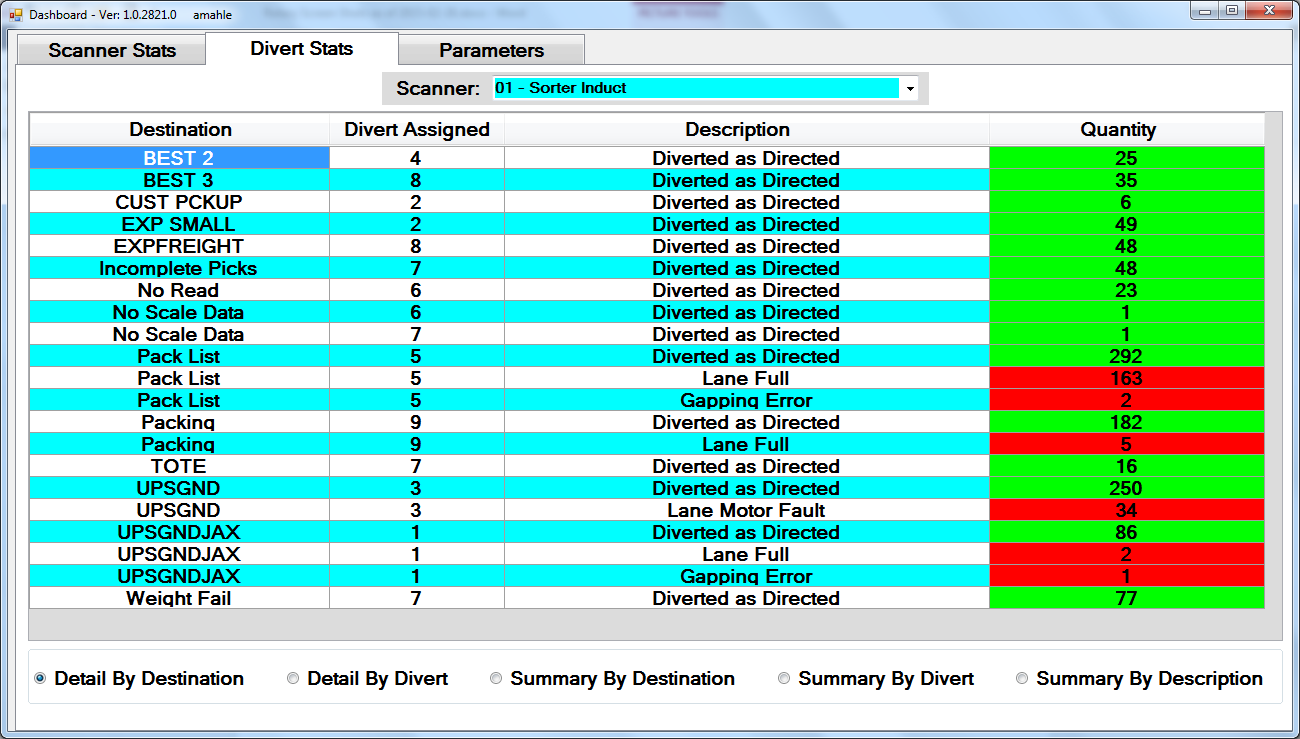

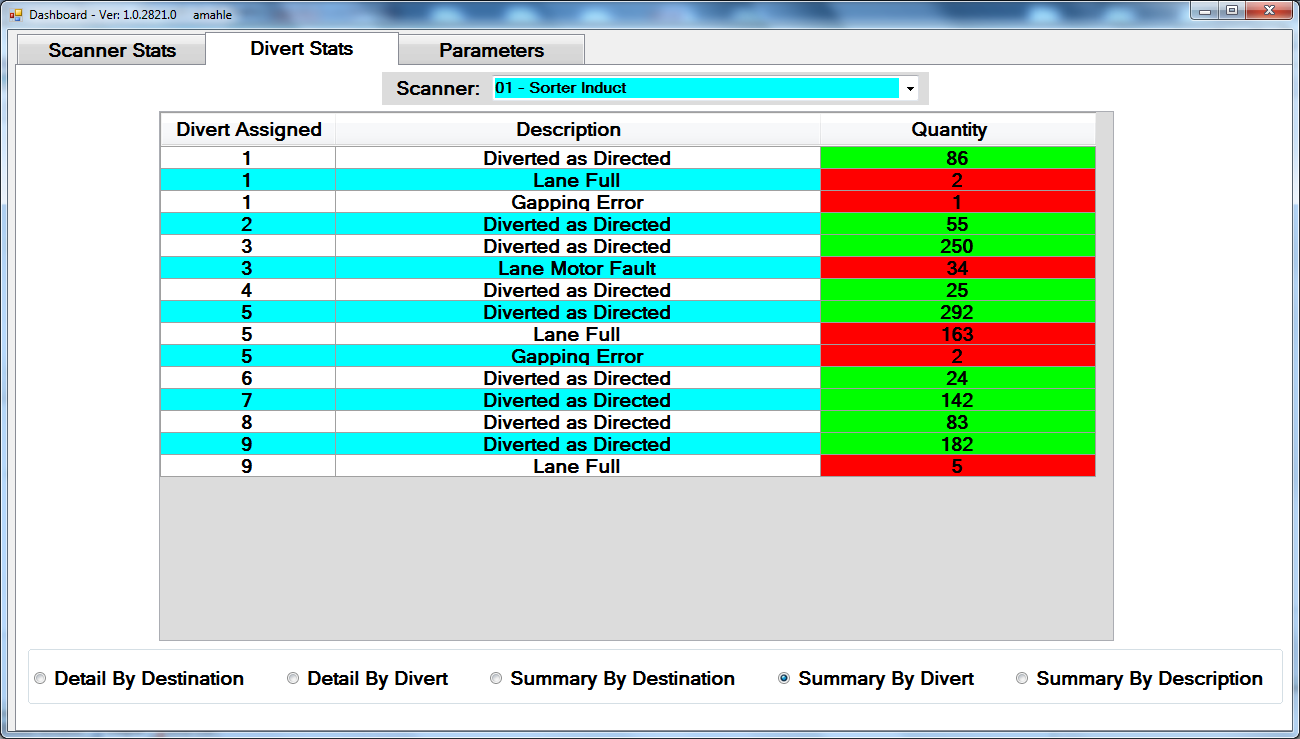

The user can also select to view the divert statistics in multiple ways. There are summary and detail displays. A few examples are shown below.

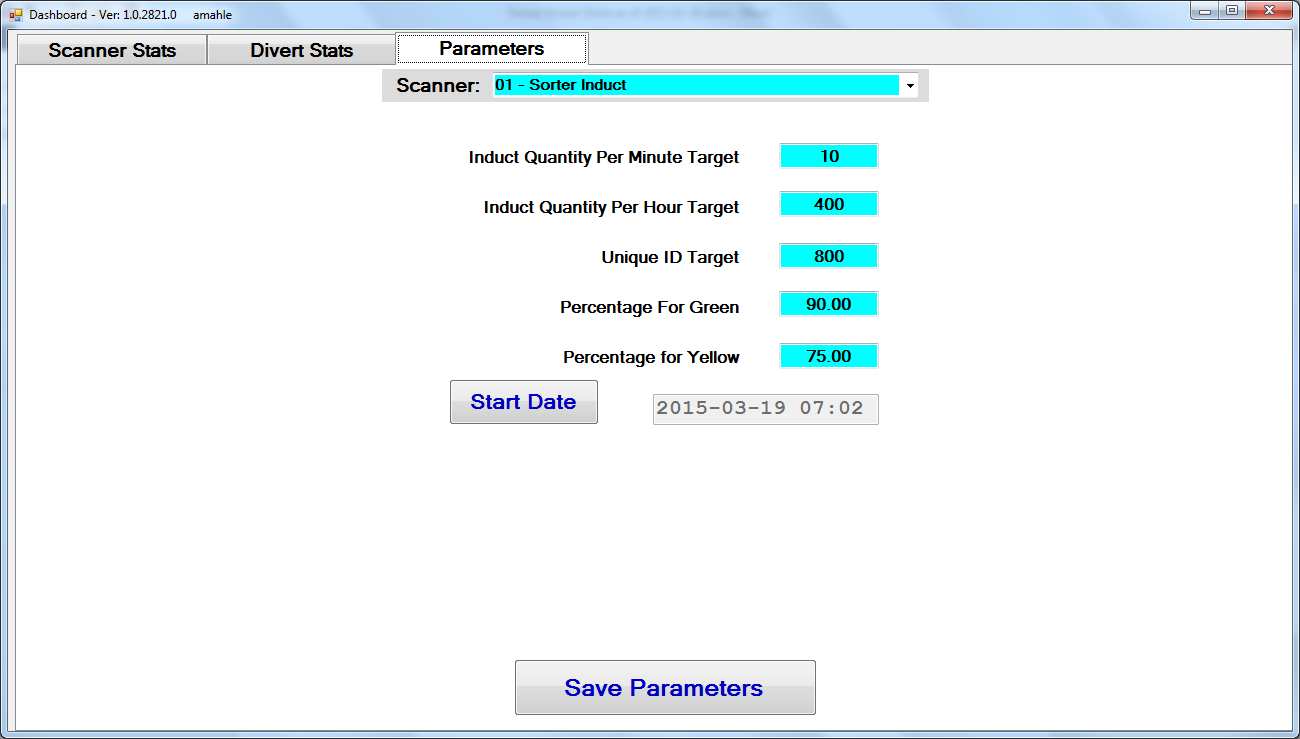

The last tab is used to set the parameters per scanner. The values entered on this tab are used to calculate the information displayed on the other screens. The values can vary by scanner to allow for different expected volumes.

Host Data Exchange - This service is used to exchange information between a host system (WMS) and MDCS. The data can be exchanged using TCP/IP sockets, shared tables, FTP and other sharing methods. One or more instances of the Host Data Exchange service may be used to maximize the data exchange rate, multiple customer computer systems or to handle multiple data exchange types. The communication method, data structure and message types are detailed in the design phase.

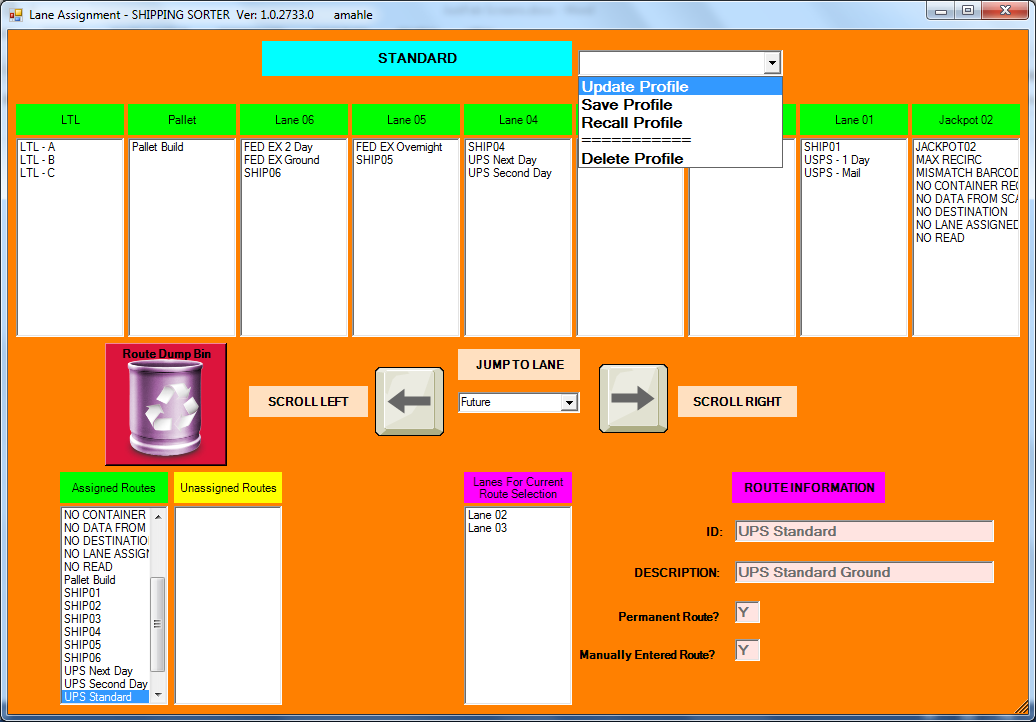

Lane Assignments – This is used to allow mapping of WMS routes or logical lanes to physical lanes on a sorter. One or more routes can be assigned to the same physical lane. The same route can be assigned to multiple physical lanes.

Picking – The Picking service interacts with the PLC to direct containers to the required picking zones within a picking module. When a carton is scanned, the Picking service uses information about the carton to determine if the carton needs picks from one or more of the zones associated with the scanner or camera. More than one pick zone can be required for a container at a divert location. MDCS can be set up to prioritize pick or to allow the container to go to the first available zone assigned for the divert location. The zone divert information is passed to the PLC which delivers the carton to the one of the required zones or allows the container to pass. It is also used to release cartons from picking once the carton is completed.

Picking Divert Confirm – This service is used to record the result of each attempted picking divert. This information is stored in MDCS tables for review and / or reporting. The divert confirmation details can also be passed back to the customer’s host computer.

Print and Apply Identify – The PA Identify service is used to identify the carton being processed and print a label. The label can be provided by the WMS system or generated by MDCS depending upon the label required.

Print and Apply Verify – This service is used to compare the label scanned at Print and Apply Identify and the label applied. It will then determine if the proper label is on the carton. The carton can then be directed as required based upon the comparison result.

Print and Apply Divert Confirm – This service is used to monitor and record the success of each attempted divert based upon the result of PA Verify. This information is stored in MDCS tables for review and / or reporting. The divert confirmation details can also be passed back to the customer’s host computer.

Reports - Reports are available to monitor the history of containers, check weigh areas, sorters, etc. The user can select date/time ranges for the reports. There are multiple standard reports. Custom reports can be added. All reports can be viewed on the screen or sent to a printer.